Posts by Bruce:

Printavo Welcomes Chris to the Team!

Chris Woolum

Printavo would like to welcome Chris Woolum to the team! Chris has been building web applications his whole life and worked with me earlier on in Printavo’s life. This is the first team member and we’re both extremely excited to take Printavo even farther.

Keeping your Screen Print Shop Clean – Ink Messes

New to screen printing or looking to streamline your operations? As a small shop operator, I found out the hard way that keeping a clean and organized shop was essential to being successful. By minimizing waste I found that I was able to maximize profits and productivity.

One of the most time-consuming aspects of screen printing is cleaning up ink. Let’s face it–it’s not very fun. These are a few things I have done in my shop to reduce the mess in handling ink.

Taking the time to set up a proper ink cabinet saved me loads of time and frustration. By lining the ink shelves with newspaper it prevented ink from touching the actual surface of the shelves and in the event of a drip or spill I would simply throw the newspaper away and replace it with fresh newspaper. Since old newspapers are free and easy to come by, I reaped the benefits of easy cleanup at no cost. With the shelves now protected by newspaper, I took a few minutes to ensure all ink containers were clearly labeled and wiped clean of any ink. Paying special attention to where the lid met the container as well as the bottom. I also discovered stacking ink containers directly on top of one another lead to more than a few disasters.

Before I start my print jobs and handle ink, I always put on an old XXXL tee on over my clothes. When handling ink I always make sure to wear vinyl gloves. These are available at most big box stores in bulk for a low price. In our shop, we keep vinyl gloves next to our ink storage and at our ink handling station. We also keep a stack of newspapers by the handling station and always lay a few out on the table before handling ink. In the inevitable event that ink drips or spills, clean up is quick and easy. We also place high absorption shop rags or recycled old, unusable tees at both the storage rack and handling table for easy access in case of a spill. Shop rags and tees tend to be more absorptive and soak up the ink much better than cheap paper towels that just smear the ink around.

When it comes to handling and storing of ink you can never be too vigilant. Even if you employ all the suggestions above you can still end up with a mess on your hands, whether it be knocking over a container or transferring a small spot from your arm to a couple of tees in production. However, I’ve found that taking these steps can dramatically reduce waste, increase production, and keep things around the shop as clean as it can be. Hopefully implementing these tips in your shop will help save you some time, money, and possibly your sanity.

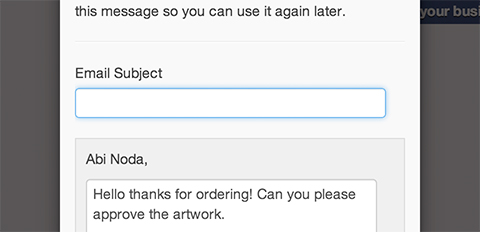

Custom email subject lines

You can now input custom email Subject Lines that are sent to your customers. This will help enable shops to have more customization when it comes to emailing out their invoices. Happy screen-printing!

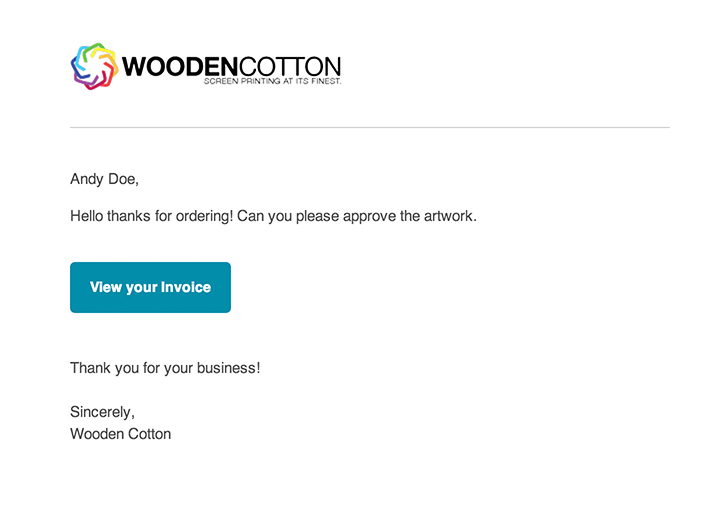

Professional Looking Emails

Hey All,

I’ve been working quite a bit on the backend of Printavo to create a foundation that is ready to scale and add tons of more features onto. Tonight I redesigned the email templates so they look more professional when being sent to your clients. Take a look below to see an example. Happy Printing!

Bruce

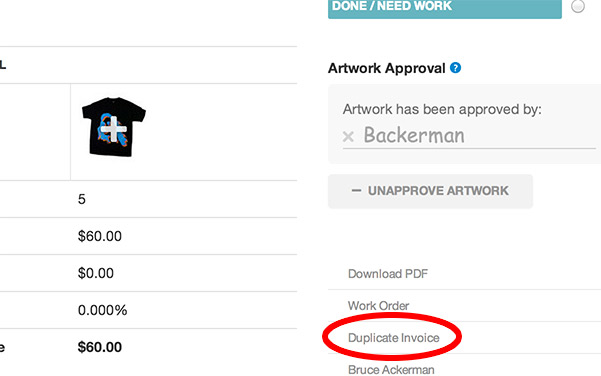

How to duplicate an invoice

If you need to create a copy of an invoice you created, follow these steps:

- Go to the invoice you’d like to copy (ex. https://www.printavo.com/invoices/123 )

- Scroll to the bottom right

- Click on Duplicate Invoice

Printavo vs The Others [Video]

A little video I put together on the woes of using another screen-printing shop management software vs Printavo! Hope you like it.

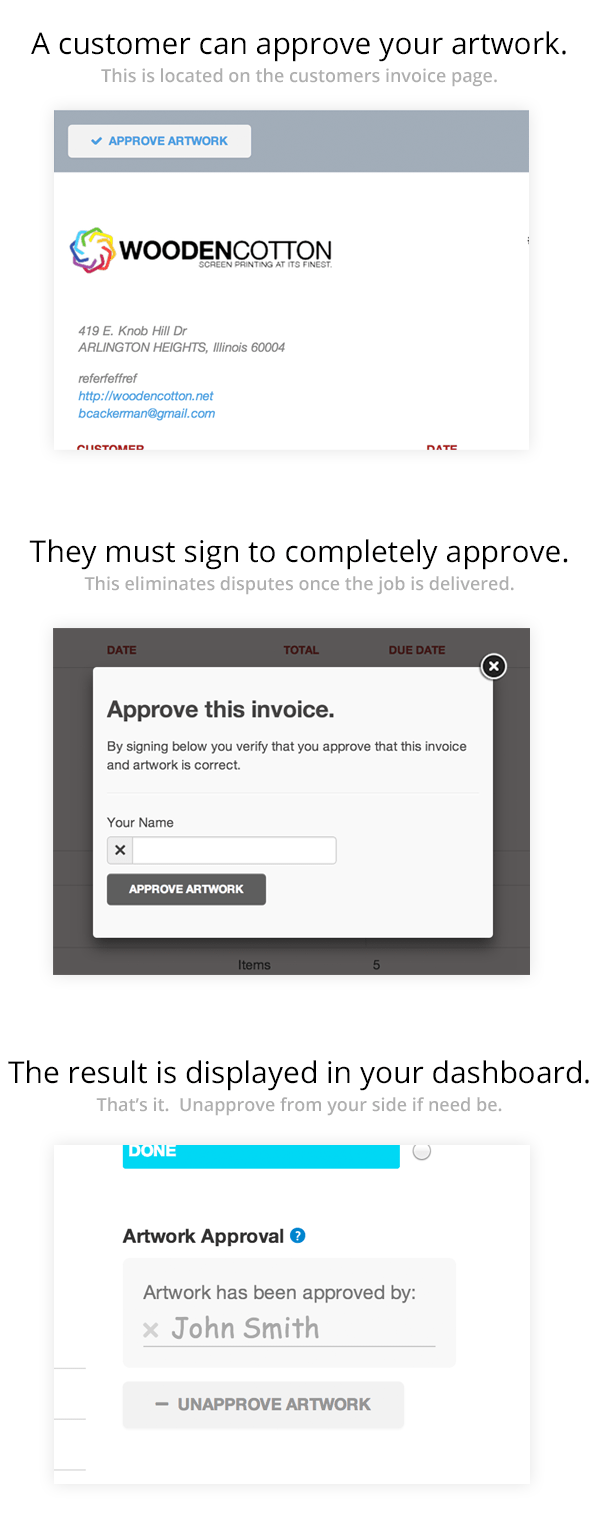

Art Approvals Are Here!

I’m pleased to announce that you can now send art approvals to your customers on the Printavo platform. Check out the graphic below to understand how it works:

How to Start a Successful Clothing Business

Bruce from Printavo again (simplest way to manage your print shop).

So the other day a friend asked how to get his clothing line up and running and I thought I would post my response up here so everyone can see.

What kinda industry are you looking to start your line in? There’s a lotta brands out there now but very few make it past the 1 year mark. When you start a lot of people are going to be like oh just another tshirt company or something but it’s all about being consistent, longevity and and constantly improving.

Being consistent means that you gota keep releasing new stuff at least twice a year (Spring and Fall is what we starting doing). Work on selling to your friends and using free/low cost promotional tools such as stickers (123stickers.com) business cards (vistaprint.com) and a skate team or some kinda team if you’re not in the skate industry that is hyped on your stuff and will help you promote it. When people see that you keep releasing things and getting better then you’ll be seen as more legit. Remember though you’re bottom line of a team is to promote so careful with giving out a ton of stuff to them. The first line or two will basically be duds and you’ll prolly lose money unless you have super hot designs or something hot that people like.

Try to print the absolute minimum to avoid that too, don’t be afraid to try embroidery or something small at first to get peoples feedback. ALWAYS ask your close friends what they think before you pay for anything, they’re give you good critism to improve and that’s what you want. We’ve made some designs that we were like “daaamn that’s so sick” and then we ask our panel of people what they think and they’re like “ehh,” so we scrapped it. A secret of Kerosin was that at first to attract new customers we made crazy designs (you can see them at kerosinclothing.com and click on Collections then click on the the lines after the first Fall ‘07 one i believe). The wild designs were to attract people to the brand and now we print simpler things because they generally sell more and people know the brand.

Brings me to my next point, unless you know the owner of a shop, they probably won’t carry you’re gear. That’s because when someone walks into a shop to buy clothing, they generally buy something because of the brand name attached to it. This means that if they see something in the shop and don’t know the brand name of it, they prolly won’t buy it. It took us prolly a year before we were able to have good brand recognition in central illinois and now more in chicago. That’s where the longevity comes into play because once people keep hearing your name, they respect it more and random people start buying it.

Lastly, you want to keep improving the brand. The way we do this is now we have higher quality shirts that cost a bit more but it matters to have that better quality. We have cleaner more improved designs each time, print our logo and size inside the shirt as a tag, bag shirts in poly bags when we ship them, give stickers out, make videos of our team, after selling shirts then get into hats, hoodies, sweatshirts, hopefully jeans. You also want to keep loyal customers buy giving them a discount too.

If you have more tips on starting a clothing line, post them in the comments.